1. Granules are made by spraying binding liquid on the powder

Agglomeration is the first technologic innovation developed from the original fluid bed dryer. We offer three types top spray systems – FL, PGL, and DPL. The powder is charged in the container of the fluid bed and fluidized by the hot air. The binding liquid such as solution, suspension is sprayed on the fluidized powder to build liquid bridges among them. The liquid bridges are dried by the hot fluid air to stick the powder together. While the liquid sprayed continuously, the particles grow bigger to a desire grain size.

Product characters

- Dust - free granules

- Low rigidity

- Low bulk density

- Wild grain size distribution

- Porous structure

- Good dispersibility

- Excellent solubility

The agglomeration process has been developed as a solidifying process for liquids. A (or more) powdery adsorbent (for example: sugar, starch) is used as a carrier and saturated by the liquid. The final granules integrate spray-dry components from the liquid and the carrier powder. Because a considerable volume of liquid must be evaporated, the drying efficiency of the processor should be high. we recommends two series fluid beds PGL AND DPL for this process.

PGL and DPL have been successfully applied to make the granules of the Traditional Chinese Medicines (TCM). It is common that a TCM prescription includes more than ten different herbs. The herbal fluidextracts are viscous and difficult to be dried. Comparing with the traditional wet-granulation process, the high efficient PGL and DPL save energy and time and reduce the quantity of the excipient significantly.

2. WET GRANULATION

Strong granules made from powder

Powder is charged into the product container of the wet-granulator ( SMG ) and wetted by binder sprayed from the top of the container. The product is intensely mixed by mixer and chopped by chopper. Normally, the granules are discharged into core sieving milling to crush oversized granules before they are dried by fluid bed dryer. The granules made by this process are harder, rounder and stronger than the granules made by top spray fluid bed.

Product characters

- Low dust granules

- Good flowing ability

- Easy to compress tablets

- Good dispersibility

- Snowball structure

- High bulk density

- Wide grain size distribution

3. Coating particles for different purposes

Many products require coating for diversify purposes such as taste masking, enteric release, release control, improved stability or aesthetics. We offers different fluid bed processes-top spray coating, bottom spray coating and tangential pray coating to meet different coating requirement. The coating material can be solution, suspension, emulsion, latex, and hot melt. The low viscosity and small droplets are required to ensure the spreading of the coating liquid on the surface of particles. The film coating is a dynamic and complicated process that is influenced by many factors such as droplet formation, droplet spreading, evaporation, core penetration by solvent etc. Each process has its limitations. For a given product, a particular best way should be chosen

The characters of Coated products:

- Good stability

- Free flowing ability

- Smooth and colorful surface

- Masking bad taste

- Enteric release

- Control release

- Keep odor

Top Spray Coating

By using the FL, PGL, and DPLtop spray system

- Particles moving randomly

- Agglomeration is unavoidable

- Long travel distance of the droplets

- Higher evaporation

- Imperfect coating film

- Unsuitable for organic solution coating

- Unsuitable for enteric or control release precise coating

- Suitable for latex or aqueous solution coating

- Applied for taste masking and colorful coating

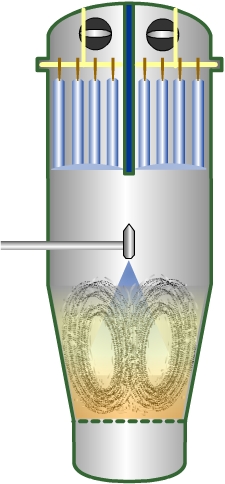

Bottom spray coating

- By using DPL bottom spray system

- Particles recycle moving between

the cylinder coating room and container

- Spray nozzle positioned at the centre of the distribution plate

- Short travel distance of droplets

- Low evaporation

- Perfect coating film

- Suitable for organic solution coating

- Suitable for enteric or control release precise coating

Rotor Coating

- By using FL and DPL tangent spray rotor system

- Powder layering for high dosage medicine 'spiral'moving patent

- spray nozzle positioned at the tangent of the disc

- Short travel distance of droplets

- Low evaporation

- Perfect coating film

- Suitable for organic solution coating

- Suitable for enteric or control release precise coating

2. Solid Medicine Process Chart

Pulveriztion---filtering---mixing granulating--drying---regulation---mixing:

1) tableting pressing---du-dust---coating---packing

2)capsule filling--polishing--packing

|